Selecting the best Filling and Discharge options for your needs can save you time, money, and help create a safer working environment.

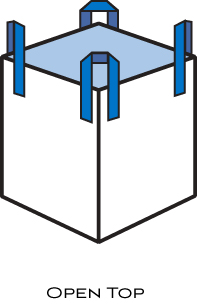

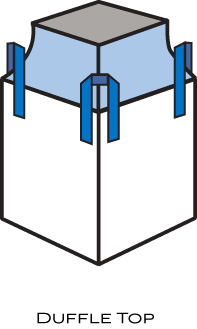

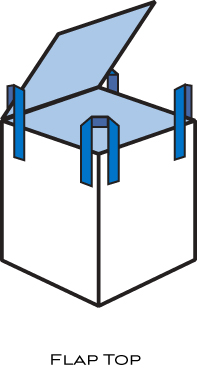

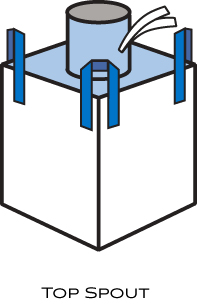

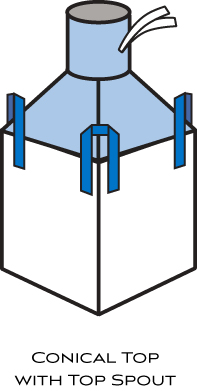

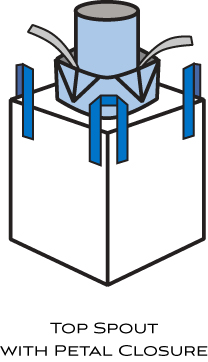

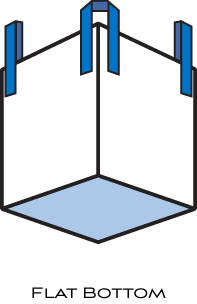

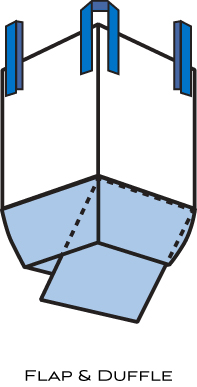

These options are best determined by the product that is to be packed in the Bulk Bag and the method required to do so. Some examples of these options you can see in the adjacent images include:

- an Open Top may be adequate for inexpensive products not prone to moisture damage;

- a Duffle Top or a Flap Top gives easy access whilst ensuring product integrity;

- a Conical Top is ideal for those materials that need time to settle;

- additional filling options such as Top Spouts further aid in the filling process, with Petal closures further enclosing the product whilst allowing air flow;

- a Flat Bottom is the economical option if the Bulk Bag is Single Trip and the product is either to be removed from the top or the bottom is to be cut for product release;

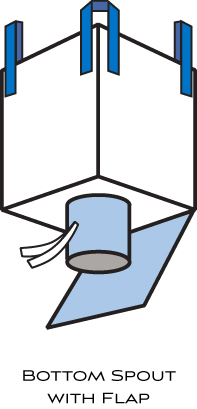

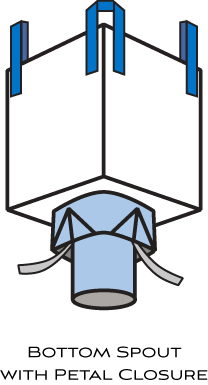

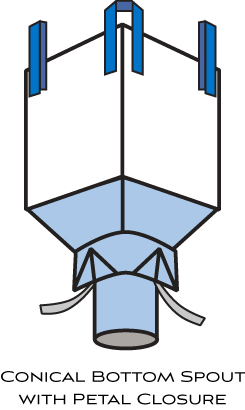

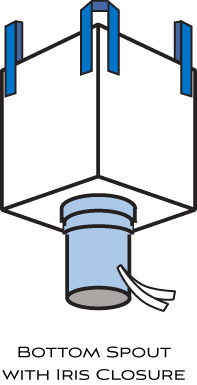

- Discharge Spouts and Conical Bottoms assist in directing & maintaining controlled release;

- with Petal and Iris Closures to aid in protection from contamination;

- Full Bottom Discharge is available if rapid release is desired.

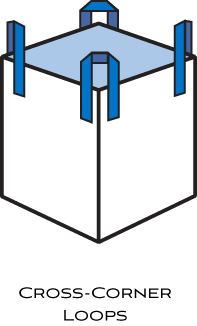

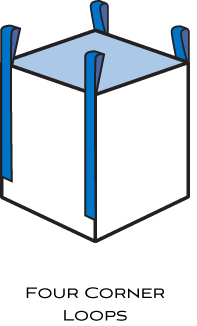

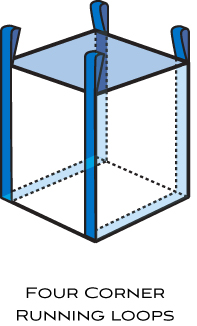

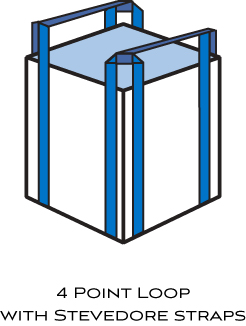

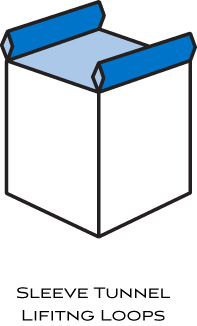

Lifting options are determined by the requirements of manoeuvring Bulk Bags with filled weights regularly exceeding 1,000kgs, with a variety of choices available to suit diverse conditions. Four Loop (generally at, or across, each corner) and Sleeve lifts are specifically designed for use with forklifts. Attaching additional straps to a Four loop bag allows the use of a hook to pick up the bag.

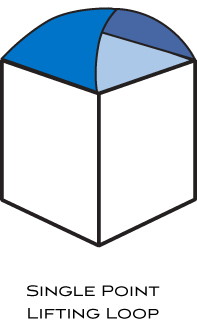

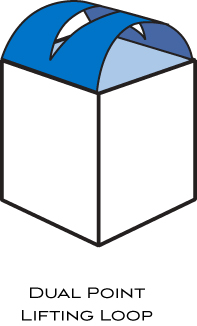

Single and Dual Point Loop bags are suitable for pick-up by either crane or forklift. These are primarily used in the agricultural industry but are also used for minerals and fine particle products. Dual Point Loop bags are used when greater access is needed when filling the bag with the loops tied together for lifting.

Four Loop bags are the most common Bulk Bags in Australia, and are used for agriculture, construction, chemicals, foods, minerals, and pharmaceutical products. These are often constructed using circular woven polypropylene fabric to reduce the number of stress points from seams. They serve a wide variety of dry-bulk handling applications, providing customers with a safe and sturdy bulk packaging solution.