Bulk Bag Constructions

Bulk Bags are constructed from a flat woven polypropylene (WPP) fabric in several ways, can be either coated or uncoated, and vary in capacity depending on the Safe Working Load (SWL) or Safety Factor (SF) requirements.

- Circular Woven – A Circular or Tubular Bulk Bag made from fabric that has been woven into a cylinder or tube of fabric, cut to the correct size. This tubular body design is ideal as a liner-less option for fine materials.

- Baffle Bags – Form-stable or Baffle Bags have corner baffles sewn in to maintain their shape when they are filled, allowing the product material to flow into all corners of the Bulk Bag and optimising packing.

- Hyperbolic™ Bags – Exclusive to Polesy in Australia, Hyperbolic™ Bulk Bags provide the benefits of a traditional Baffle Bag without the need for sewn in baffles, reducing cost, weight, and complexity of manufacture, and allowing for quicker and easier filling and discharge.

- U-Panel Bags – Made from 2 pieces of fabric with 2 seams along 2 opposite sides

to create 2 panels into a “U” panel shape. - Four+One Panel Bags – the original WPP Bulk Bag design – requires seams along five separate pieces of fabric sewn to create a four+one panel bag.

- Ventilated Bags – A section of each side of the Bulk Bag is vented to allow airflow throughout the contents of the bag, most suitable for use in the agriculture industry for produce such as onions, potatoes, and garlic.

Bulk Bags are also designed as either Single Trip bags (to be used for one filling and discharge only) or Multiple Trip bags (which are reuseable, for multiple fillings and discharges).

Bulk Bag Types

- Type A – No special electrostatic safety features; use to safely transport non-flammable products, not to be used for combustible materials or used in flammable or combustible environments.

- Type B – As Type A but with an insulating fabric to prevent propagating brush discharges; use to safely transport dry flammable products, do not use in flammable or combustible environments.

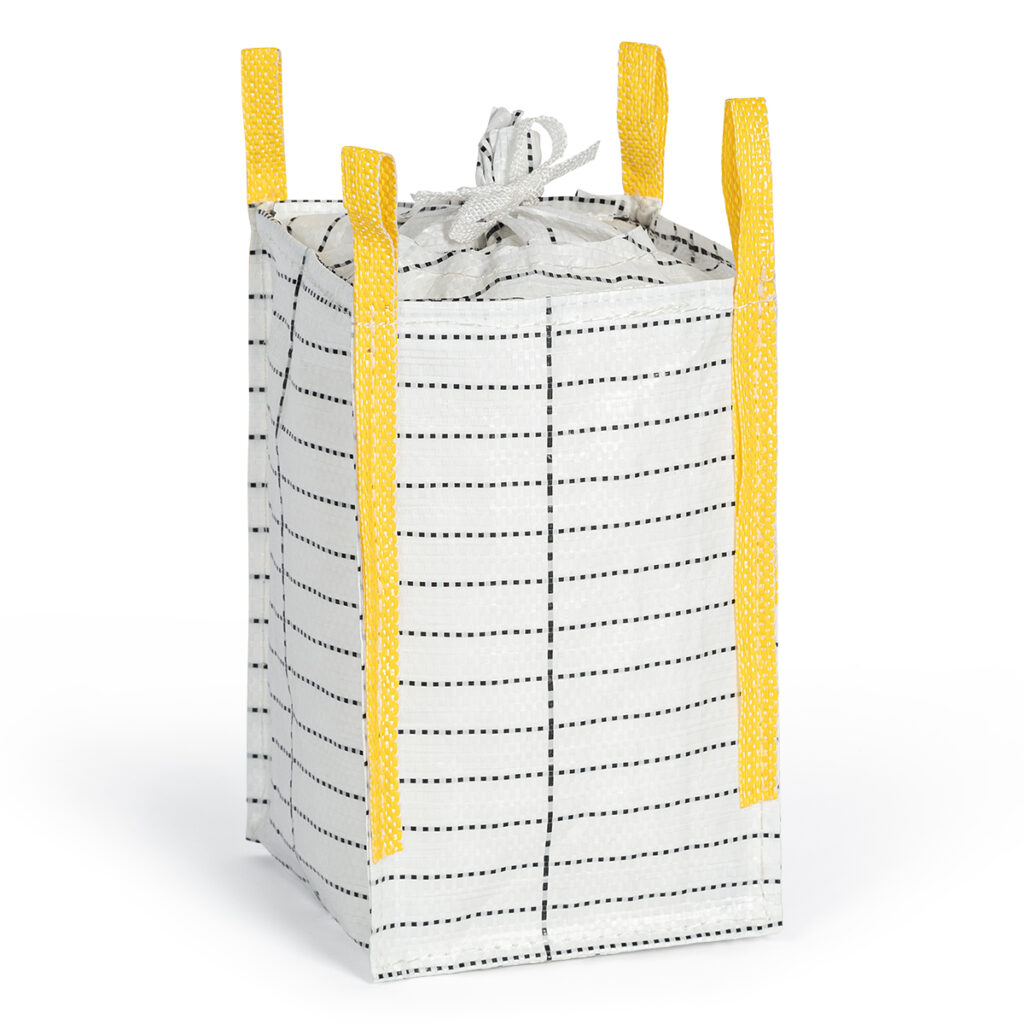

- Type C – Conductive or groundable Bulk Bag; woven with conductive yarns in a grid pattern, it is essential that these bags are electrically grounded during filling and discharge; use to safely transport flammable powders, and can be used in flammable or combustible environments provided the bag is properly grounded.

- Type D – Antistatic Bulk Bags, constructed from antistatic fabric that has antistatic or static dissipative properties and does not require grounding; use to safely transport flammable powders, and can be used in flammable or combustible environments.

- Food Grade – Bulk Bags manufactured to a food safety standard in a facility certified by a food safety standard certifying body.

- UN Certified – Bulk Bags manufactured to handle products that the United Nations considers hazardous material (also referred to as UNDG – United Nations Dangerous Goods – FIBCs).

The below Dimensions / Configurations / Lifting Options / Constructions / Safe Working Loads (SWLs) / Safety Factors are our standard offerings; customised solutions are available to suit your needs.

Dimensions

- 60x60x60cm

- 90x90x60cm

- 90x90x90cm

- 90x90x100cm

- 90x90x120cm

- 90x90x140cm

- 90x90x160cm

- 90x90x180cm

- 95x95x100cm

- 90x90x120cm

- 95x95x140cm

- 95x95x160cm

- 95x95x180cm

- 100x100x160cm

- 98x98x140cm Hyperbolic™

- 98x98x160cm Hyperbolic™

- 105x105x120cm

- 105x105x140cm

- 105x105x160cm

- 105x105x170cm

Configurations

- Top Open Flat Bottom

- Top Open Bottom Spout

- Top Duffle Flat Bottom

- Top Duffle Bottom Spout

- Top Flap Flat Bottom

- Top Flap Bottom Spout

- Top Spout Flat Bottom

- Top Spout Bottom Spout

Safe Working Loads

- 750kg

- 1000kg

- 1250kg

- 1500kg

- 2000kg

Lifting Options

- 4 Cross-Corner Lifting Loops

Uses & Safety Factors

- Single Trip 5:1

- Multiple Trip 6:1

Features

- Lamination

- Polyethylene Liner

- Static Control

- Sift Proof